Timbercraft Building's "Claim to Frame"

Cornerstone Building Company is committed to a policy of "Quality Work at a Fair Price with an Honest Guarantee" and we want to be your building of choice with our Timbercraft Buildings. In addition to providing a quality building product, we want to also provide a quality business experience with straightforward, positive communication minus the unnecessary hype or exaggeration. So before you decide on any building company please get the facts necessary for an informed decision.

Many Claim to be “The Best, The Finest, or The #1 Choice” So Who Really Is? Consider a 36’ Wide x 48’ Long x 12’ Eave Height Building Comparison

Foundation

Timbercraft Buildings: Included

Others: Optional

Unless a monolithic concrete slab foundation is provided, our typical below-grade concrete footing foundation is a necessary and included component designed to provide adequate wind load protection for our buildings.

Roof and Wall Panels

Timbercraft Buildings: Heavier & Stronger 26-Gauge Thickness

Others: Thinner & Weaker 29-Gauge Thickness

Our typical premium grade 26-gauge metal roof and wall panels are coated with a 25-year galvalume substrate, a 40-year premium paint finish and are installed with long-life screw fasteners. This application provides superior strength, durability, structural integrity and wind load protection.

Bay Spacing

Timbercraft Buildings: 4 Wider Bays Spaced @ 12'

Others: 6 Narrower Bays Spaced @ 8’

Our typical doubled truss roof framing design method offers more rigidity than single truss methods, a wider standard bay spacing, a less obstructed interior framing environment, and wider exterior door possibilities between our typical support column spacing.

Roof Member Framing

Timbercraft Buildings: 10 Roof Trusses

Others: 6 Roof Trusses

Our typical doubled truss roof framing member design requires more material than other companies' single truss methods providing a more substantial interior framing environment, wider bay spacing, and wider exterior door possibilities between our typical support column spacing.

Roof Purlin Framing

Timbercraft Buildings: 2 x 6 Roof Purlins for 5½” of Wind-Load Protection

Others: 2 x 4 Roof Purlins for 3½" of Wind-Load Protection

Timbercraft Buildings: 4 x 6 Purlin Blocks for 3½" Additional Roof Purlin Support

Others: None

Our typical roof purlin framing materials are 2 x 6 #2 grade southern yellow pine. These members are typically installed over additional 2 x 6 #2 southern yellow pine purlin supports or as lapped connections fastened to our typical 4 x 6 truss blocking. This application provides superior truss support, purlin connections, and structural integrity.

Structural Columns

Timbercraft: (10) 6 x 6 Solid Sawn PT

Others: (14) Triple 2 x 6 PT and SYP Nailed Together

Our typical solid-sawn, continuous-length, pressure-treated columns provide comparable and continuous strength in each direction. Because they are solid-sawn, their structural integrity is equally consistent and not reliant on how well several boards may or may not be nailed together.

Wall Girt Framing

Timbercraft Buildings: Shelved 2 x 6 for 5½" of Wind-Load Protection

Others: Flat 2 x 4 for 1½" of Wind-Load Protection

Our typical wall girt framing materials are 2 x 6 #2-grade southern yellow pine installed as a “shelved” versus “flat” assembly. This provides over 3½ times more wall framing depth for superior wind load protection and structural integrity.

Baseboards

Timbercraft Buildings: 2 x 8 PT

Others: 2 x 6 PT

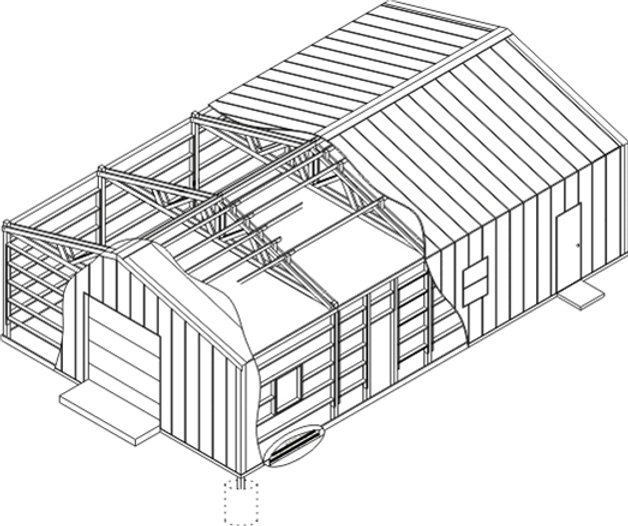

How a Good Plan Comes Together

- SOLID SAWN PT COLUMNS: Sized to meet Load Requirements, Treated for Below-Ground Use with Comparable Strength in Each Direction.

- MONOLITHIC TYPE CONCRETE FOUNDATION: Two Rows of Continuous #5 Rebar Reinforcement with One Row Installed Through Columns for Increased Uplift Protection.

- COLLAR TYPE CONCRETE FOUNDATION OPTION: Individual Footings Poured Around Column with Spikes Installed Into or Through Columns for Increased Uplift Protection.

- PT BASEBOARDS: 2 x 8 Nominal Width to Minimize Concrete Spillage at Bottoms of Footings and Treated for Ground-Contact Use.

- SHELVED WALL GIRTS: Superior Wind Load, Enhanced Fire Blocking Capabilities with Minimized Additional Framing Costs Required to Prep for Interior Wall Finishes.

- “DOUBLED” TRUSS & RAFTER SYSTEM: “Sandwich-Type” Column Connections with Hot-Dip Galvanized Lag and/or Bolt Fasteners.

- 12’ STANDARD BAY SPACING WITH 4X PURLIN BLOCKS AND LAPPED OR SUPPORT BLOCK TYPE PURLIN CONNECTIONS: Increased Top Chord and Roof Purlin Support, Minimizes Splitting at Framing Connections & Provides for Flexible Bay Spacing.

Although this information is typical, it is not meant to be exclusive in design. Cornerstone Building Company reserves the right to make changes and/or certain modifications to this information that it may deem necessary and/or appropriate.